Howto unclog your j-head peek barrel of melted PLA

So it happened that for some reason the home switches of the 3d-printer with firmware were not operating as it should have and it caused the Z to be misaligned. The misalignment then took the nozzle too close to print bed and blocked the melted plastic exit route from the hotend causing extruder to squeeze too much plastic “all over the place”. And as the problem was not spotted right away there was some heat related issues.

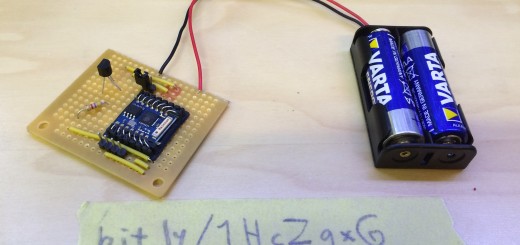

Ok. J-head full of plastic and not getting anywhere

- Tried to heat the hotend to some 180C to melt the plastic and just pull it out, did not work

- Unmounted the hotend from the extruder assembly and repeated step one. Not helping

- We took the J-head apart and the plastic on the incoming side was still stuck

- With a knife as we did not feel comfortable heating it with torch we then dug the excess plastic off of the set-screw to gain access to the screw to unscrew it. It took some 30 minutes to dig the screw.

- Unscrew the set-screw and with it came the PLA blob. From the screw it was easy to remove the extra plastic. The PTFE liner was intact.

- Screw it back together

- Pray for calibration as the J-head does not that well align it in the same height as it was

- Calibrate Z

- Calibrate more Z

- Try some test prints

- Go home

Nice and easy Wednesday evening. It was social enough though but I had some other plans originally.

Thanks to #reprap@Freenode for the tip with set-screw

Get your genuine J-Head from the maker of genuine J-head hotends @ http://hotends.com

And other than this self caused/user error problem the hotend has really worked like a charm. No problems whatsoever.