Mendel90 design improvements (aka fixing broken parts)

For some time the quality of prints has been varying. Occasionally pretty nice prints and on other takes something straight to trash. One time upon inspecting the matter I realized the x belt is not as tight as it is supposed to be. Fair enough there is a screw to apply more tension. That did help a bit but on closer look I realized the motor end of x axis is not perfectly aligned to the rods – more like bent because of the force caused by the belt. Uhm. OK. The fittings where smooth rods are inserted on both ends had a design flaw and thus caused the part to break and loose the friction.

I had already beforehand spotted from Nophead’s blog the improved design of those parts but I did not know the improvements were also for this problem. So no problem – printed the parts to wait for better time to take the printer apart. Not too easy with a bit out of focus printer but manageable. The parts then did sit on the shelf waiting for need and motivation.. As I was printing something else some other day I spotted the extruder to move a bit, tilt or jump depending on if it was extruding or retracting. Weird. I tried looking at the symptoms but did not spot anything in particular.

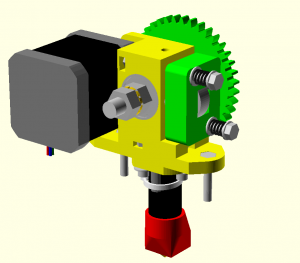

The next day again printing some random parts and realized the the body of extruder to be in two parts. Nice cracks on both sides of the bolt so the extrusion was done by pure luck. I am not sure how I did not spot this but the cause to find it was malfunction in filament feeding. As the filament stopped moving lacking the pressure on the idler. Now it was time to try to print a replacement wades block and install the parts.

Job halfway done. Part printed, mostly “installed” as the x-axis is off the printer at the moment but extruder is supposedly fixed and the axis is waiting for some M3x45 bolts so work in progress. Tomorrow is then scheduled for finishing up the build and calibrating, calibrating, calibrating.

Great printer. Kit still available from Nophead.